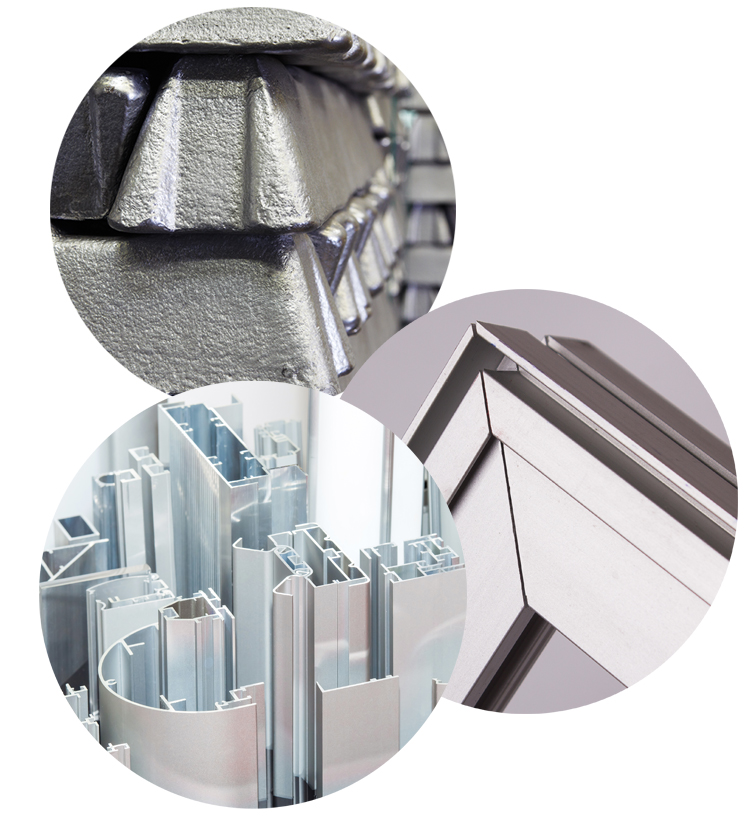

GC Aluminum, Inc manufacturing procurement sources ingots exclusively from Australia or Malaysia.

- Our initial process involves the ability to convert all aluminum ingot in billet form for our production processing lines

- Aluminum alloys of 6005, 6060, 6061, 6063 and 6105 with aluminum extrusion profiles of up to eight (8) inches circle width

- Vertical and Horizontal Powder Coating Paint Systems meeting 2603 – 2604 and matching existing paint inventories to +/- 5% delta

- Complete Aluminum Anodizing processing with full range of colors and sublimation finishing meeting (AAMA 611 Class 1 & 2)

- Complete myriad of shapes, tubes, rods, slats, window profiles, structural components and thermal break custom outlines

Aluminum Anodizing

- Electrochemical Anodizing process for lengths up to 24 feet

- AAM10C12C22A211 (201R1)

- AAM10C12C22A21 (202R1)

- AAM10C12C22A31 (204R1)

- AAM10C12C22A41 (215R1)

Anodizing Descriptions:

- Clear Satin Anodized

- Medium and Dark Bronze Duronotic

- Developing Bright Dipped Anodized

The anodizing process of aluminum converts the surface of the metal into a long-lasting high performance aluminum oxide finish. This process integrates into the aluminum alloy metal and will not peel or chip, unlike surface applied finishes. It allows the component increased resistance to corrosion and significantly increases the hardness of the metal resulting in a high performance, hard coat finished surface.

One of the major benefits is it allows the component increased resistance to corrosion. It provides a significant increase in the hardness of the aluminum alloy metal resulting in a high performance, hard coat finished surface.

Anodizing Aluminum Benefits:

- Durability

The finished product life cycle would exceed all other finish forms - Consistent color

Anodizing dyes seep into the metal making them very stable. Anodized aluminum maintains its color in spite of exposure to UV rays. It will not flake, peel or chip, and extrusions will look factory new for years. - Low maintenance Costs

Evidence of wear or abrasions from the extrusion process, installation, or from frequent handling and excessive cleaning are rare. Anodized aluminum is easily restored to its original luster with gentle cleaning. - Aesthetics

Anodized aluminum maintains its metallic appearance but can easily accommodate color and gloss applications. - Value

Finishing costs and maintenance costs are low, giving anodized products a better value in the long term.

Aluminum Paint Applications

GC Aluminum offers the highest quality aluminum extrusion paint finishes globally

- Horizontal Powder Coating paint line lengths from two (2) feet to 26 feet

- Complete array of RAL Solid colors and Wood Grain patterns available

- Flat Matte Finishes

- Textured Finishes

- Flex Paint Finishes

- Specification AAMA 2603 – 2604 to North American Standards and +/- 5% through spectrometer and matching existing inventories.

- Highest degree and quality and precision work for your application.